Virtual battery technology will help electric vehicles lose 25 pounds

Time:2022-01-27

Views:2203

Consumers who choose to replace their cars with pure electric vehicles (BEVS) want to use large lithium-ion battery packs to power the motors. In addition, they may be surprised to find that conventional 12 volt (12V) batteries handle the same functions required by many fuel vehicles.

This somewhat unexpected finding can be explained by the fact that automobile manufacturers are trying to overcome a major design problem: the lack of a coordinated and scalable power supply scheme, which can supply power not only for motors, but also for all automobile subsystems supported by 12V for a long time.

This complexity is exacerbated by the sharp increase in power demand. Pure electric vehicles require 20 times more power than fuel vehicles. A 20x surge means a corresponding increase in electronic equipment, which increases cost, weight, size and design complexity.

The current suboptimal solution is to equip electric vehicles with up to three independent batteries: a 400V or 800V (traction battery) and a distribution system powered by 12V and 48V secondary batteries.

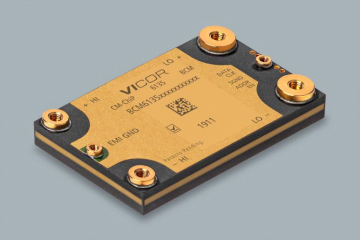

The best solution to this design dilemma is whether the traction battery can have the same capacity as the 12V battery. Using VICOR solid-state high-efficiency power module converter in combination with sinusoidal amplitude converter, you can copy the system requirements of 12V battery, which is essentially to create a virtual battery.

Patrick kowalyk, chief field application engineer of VICOR, said: "VICOR is working with automotive suppliers and OEMs to eliminate these supplementary power supplies by creating a ‘virtual battery‘ that responds three times faster than 12V. The solution is a high-performance modular power converter that can step down the power supply from a 400V or 800V high-voltage main battery to 12V or 48V. The response time is so fast that a separate battery is no longer required 。”

This replacement strategy not only allows engineers to copy the basic properties of 12V physical batteries, but also helps them reduce the weight of their car by more than 25 pounds and save enough space, which is the size of a small suitcase to carry with them. In 2022, OEM manufacturers are expected to adopt this modular power supply scheme.

They hope to realize the electrification and differentiation of their automotive product series by increasing driving mileage and improving overall performance.

Figure 1: to eliminate the 12V battery, the traction battery needs to have the same capacity as the 12V battery. Using the VICOR solid-state high efficiency power module (BCM 6135) in combination with a smaller converter, you can copy the power system of 12V battery, which is essentially creating a virtual battery.

|

免责声明: 本文章转自其它平台,并不代表本站观点及立场。若有侵权或异议,请联系我们删除。谢谢! |