Mass production and shipment! Nanocore micro high-performance vehicle specification LDO brings new choices for vehicle power design

Time:2022-11-27

Views:1398

The NSR31/33/35 series, the first car size LDO chip newly released by Nanochip Micro in 2022, has been officially mass produced and supplied in batches to well-known international auto parts manufacturers.

01 Wide input voltage range

02 Ultra low static power consumption

03 Multiple protection functions and high reliability

04 Multiple packaging options for easy design

LDO chip is a kind of low voltage differential linear regulator. With the development of automobile electrification and intelligence, LDO becomes more and more important in the design of vehicle power supply, especially in low-voltage applications such as vehicle power supply, vehicle infotainment system, body control, automatic driving, etc. NSR3x series products are specially designed for automotive battery power supply systems. Their wide input voltage range, ultra-low static power consumption, multiple protection functions and multiple packaging forms bring new choices for engineers to develop power modules for on-board applications.

01 Wide input voltage range

Different from consumer electronics such as computers and household appliances, automotive application scenarios are changeable, and the power supply voltage is prone to large jumps under cold start and load shedding conditions. The international standard ISO 7637 is an electromagnetic compatibility standard set by the standardization organization for 12V and 24V power supply systems of automobiles. Among them, ISO 7637-2 is a test standard for the ability of power modules in automobile applications to cope with transient voltage changes. Through designing a series of transient voltage tests, it simulates all electrical faults that automobiles may encounter in real application scenarios, such as load shedding. The design standards of many vehicle manufacturers refer to ISO 7637 standard, and some manufacturers have made changes to the standard to meet their own needs. ISO 7637 also includes electromagnetic resistance and emission specifications for electromagnetic compatibility testing. These standards are set to enable the vehicle manufacturer to check whether the power system design has electrical faults through tests before leaving the factory.

The complexity of the automotive application scenario requires that the LDO chip in the vehicle power module has a wide input voltage range, so as to ensure the stability of the LDO post stage output and prevent the LDO chip from being damaged due to power supply voltage fluctuations.

NSR3x series LDOs launched by Nanochip Micro are specially designed for the automotive battery power supply system. They have a wide input voltage of 3V to 40V, support transient voltage up to 45V, and can provide stable and reliable power input for LDO subsequent devices, so as to ensure that the functions of the corresponding modules can be correctly realized under various complex working conditions, and extend the service life of the corresponding modules.

02 Ultra low static power consumption

As one of the largest sources of carbon emissions, automobiles have been developing in the direction of energy conservation and emission reduction. Both new energy vehicles and traditional vehicles have placed great emphasis on energy conservation. However, new energy vehicles have higher requirements for power consumption control of various components due to the use of battery power supply, and the current charging speed and charging facilities are not perfect. Inductive wiper, automatic headlight, inductive trunk and other functions will not work until the starting conditions such as rain or dark are triggered. Before the function is started, the power consumption should be kept as low as possible, which requires that the static power consumption of LDO and other chips in the module is low enough.

When the NSR3x is turned off, the current is only 270 nA, while the typical value of the static current is 5 uA under light load. When the external power supply reaches 0.2 mA, the typical value of the static current is 6 uA. The power consumption index under the low power consumption mode is excellent. NSR3x is used to supply power to MCU and CAN/LIN transceiver in standby system, which not only saves power, but also prolongs battery life. It is very suitable for application scenarios requiring high standby power consumption.

03 Multiple protection functions and high reliability

On board components are often subject to various extreme temperatures and weather tests, such as high and low temperatures and heavy rain and snow. Therefore, the operating temperature range of the vehicle gauge components is much wider than that of the consumer grade components. The consumer electronic components are generally required to work normally at 0 ℃ to 70 ℃, but the requirements for the vehicle gauge components are much higher. The minimum temperature range is - 40 ℃ to 85 ℃. The components around the engine and other high heat generating components often need to support 125 ℃ high temperature applications.

In addition, automobile applications emphasize safety and reliability, so LDO is required to have self-protection function to deal with accidents in complex and harsh application scenarios. For example, LDO output is short circuited to ground due to short circuit of connector or solder slip, which has a great risk. If there is no protection circuit, the current surge will cause LDO burning and other safety risks.

The NSR3x can work normally under the ambient temperature of - 40 ℃ to 125 ℃, and the short circuit protection and over temperature protection functions are integrated internally to ensure that modules designed with NSR3x can work normally under various scenarios.

04 Multiple packaging options for easy design

In the application of LDO vehicle gauge, heat dissipation design should also be paid attention to. Because LDO is usually used in modules with poor air circulation or even no air flow, if the heat dissipation design is not good enough, LDO and its modules will quickly heat up when the ambient temperature is high. Therefore, it is important to choose the appropriate package for the appropriate application and do a good heat dissipation design.

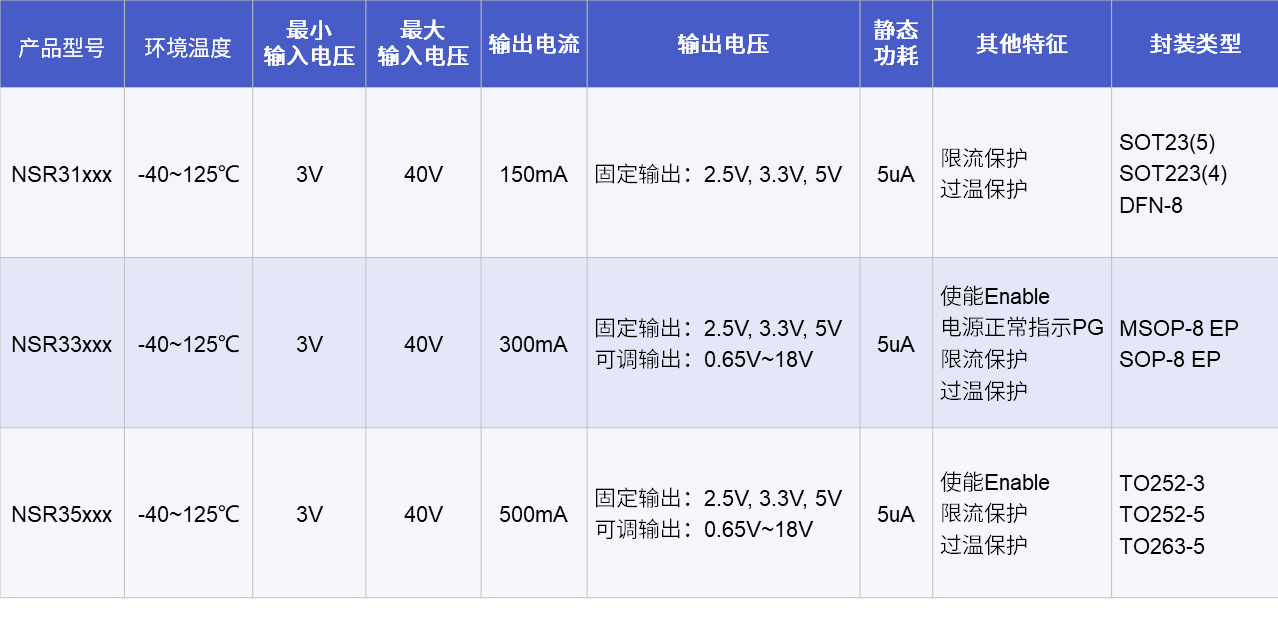

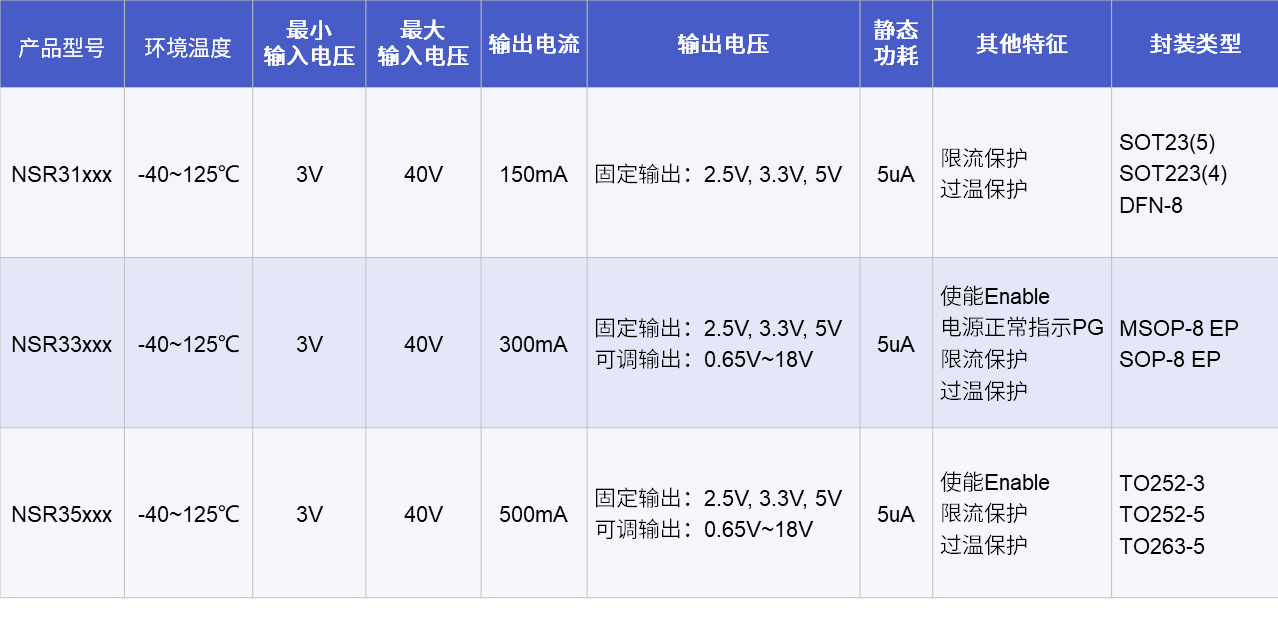

The NSR3x series is divided into three products. The maximum output current of NSR31 is 150mA, the maximum output current of NSR33 is 300mA, and the maximum output current of NSR35 is 500mA. For different current output capabilities, the nano core micro optimizes the packaging and heat dissipation design, providing SOT223, SOT23, DFN-8, MSOP-8EP, SOP-8EP, TO252, TO263 and other packaging options. Users can choose the corresponding packaging according to the actual application to optimize the heat dissipation and size design of the entire module, According to the selected package, the structure design and circuit board layout and routing are determined, so as to achieve a better balance between performance and cost.

Selection Table of Nanocore Micro LDO Linear Regulator

The introduction of NSR3x series is the embodiment of the further expansion of the layout of the car mounted products of the Nanochip Micro. At present, nano core micro has provided semiconductor products such as sensors, signal chains, isolation, interfaces, sampling, drives, and power supplies for automotive applications. Many of these products have been highly recognized by domestic and foreign vehicle manufacturers, and have been put into mass production. In the vehicle market, Nanocore has built an independent core technology matrix, and has established a complete product development, quality management and capacity assurance system. Nanocore is bringing more driving force for the upgrading of the automotive industry with hard core technology.

|

Disclaimer: This article is transferred from other platforms and does not represent the views and positions of this site. If there is any infringement or objection, please contact us to delete it. thank you! |