PCB design of battery charger circuit

Time:2023-03-08

Views:1129

1 Introduction to Protel software

With the rapid development of electronic information technology, the hand-designed PCB (printed circuit board) of electronic products can no longer meet the needs of the development of electronic technology. We must complete PCB design with the help of computer. It is not only fast and accurate, but also can greatly reduce the labor intensity of engineering and technical personnel. There are many kinds of software involved, among which Protel is a classic one.

Protel is a circuit aided design system launched by Altium. It is the first board-level design system that integrates all design tools, including schematic design, PCB design, circuit simulation, PLD design, etc. Its earliest version was the TANGO software package, and later developed into Protel for DOS, Protel for Windows, Protel 98, Protel 99 SE, Protel DXP and Protel 2004. With the continuous upgrading of the version, its functions become more and more powerful.

Compared with other versions, Protel 2004 has many new functions, which make the operation simpler and the degree of automation higher, so that we can easily design various complex circuit boards.

2 PCB design

PCB is the abbreviation of printed circuit board in English, which is translated into printed circuit board, short for circuit board or PCB board. The printed circuit board is a conductive circuit and component package made by printing. Its main function is to realize the fixed installation of electronic components and the electrical connection between pins, so as to realize various specific functions of electrical appliances. Making correct, reliable and beautiful printed circuit boards is the ultimate goal of circuit board design.

The general process of PCB design includes: preparation for production, production of PCB component pin package, new PCB file, planning of circuit board, loading of component pin package and network, layout, wiring, DRC design rule check, etc.

3 Ni-MH battery charger PCB design

Ni-MH battery charger is a common electronic product in our life. The basic steps for designing the printed circuit board (PCB) of the circuit with Protel 2004 are as follows.

3.1 Create project documents

To facilitate the management of design documents and the seamless connection and synchronization between them. In Protel 2004, project files are used for management. First, create a project file, and then create or add design files under the project file.

3.2 Create schematic file and complete schematic design of battery charger circuit

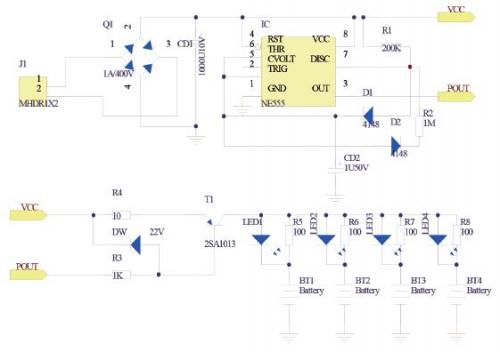

The circuit schematic diagram of Ni-MH battery charger is shown in Figure 1 below.

Figure 1 Schematic diagram of battery charger

3.3 Create PCB file and plan

In Protel 2004, there are two ways to create PCB files: create with the file menu and create with the wizard. Note that the PCB file created with the wizard is not in the project file. After the creation, you must put it in the project file, otherwise the following steps cannot be carried out. According to the composition of the charger circuit, first plan the shape of the board to be rectangular, and determine the size of the board to be 2400 mil according to the number of components × 1300mil, single layer wiring is designed as single panel.

3.4 Load component pin package and network and perform component layout

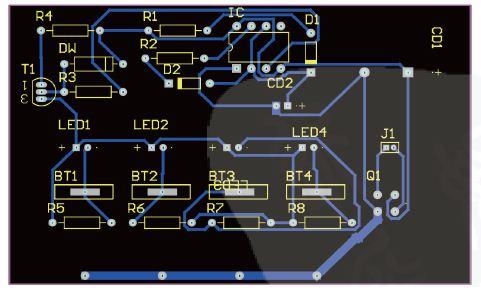

All components in this circuit are in the form of socket packaging. In addition to the packaging of the positive polarity of the battery pack, other components are packaged using the standard packaging in the Protel 2004 component library. We need to set the packaging for the positive polarity end of the battery pack according to the actual circuit. First, create our own component packaging library, create the packaging in the library as shown in Figure 2 BT1 - BT4, and then set this package as the packaging of the battery pack.

Figure 2 PCB diagram of battery charger

The component layout can be carried out automatically and then manually. Note that the transformer is not placed on this board. During layout, the arrangement and distribution of components should be reasonable and uniform, and strive to be neat, beautiful, and meet the requirements of circuit structure and technology.

3.5 Set wiring rules and conduct wiring

The so-called "wiring" is to use printed wires to complete the wiring relationship of components in the schematic diagram. After completing the layout of components on any circuit board, the next thing to do is to connect the components with wires to make them have electrical characteristics, thus forming a complete circuit board.

When wiring in Protel 2004, the wiring rules should be set first to meet the electrical requirements such as safety principles. According to the actual requirements of the charger circuit, the safety spacing is set here as 10mil, the top wiring, the common line width is 10mil, the power line is 20mil, and the ground wire is 30mil. The wiring adopts automatic wiring, and the unqualified parts can be manually modified at last. On the premise of meeting the safety principle and other electrical requirements during wiring, the wires should be simplified, as short as possible, with as few turns as possible, and strive to be simple and clear.

In addition, the wiring design should consider whether the assembly is convenient. Finally, the board is also required to be beautiful and economical. Good PCB wiring is beautiful, and the work is fine. It looks like a work of art.

3.6 DRC design rule check and error elimination.

After the design of the circuit board is completed, in order to ensure that the design work carried out meets the requirements, the computer can automatically complete the inspection work, that is, DRC design rule inspection. After the check, the system will pop up the Messages message box, and modify the design according to this message prompt until there are no errors. The PCB design of the circuit is finished here. The designed charger PCB file is shown in Figure 2 above. Finally, you can print and output drawings and reports, and carry out the corresponding follow-up work such as actual plate making.

4 Summary

Using Protel 2004 software for PCB design is easy to operate and highly automated. The PCB design of Ni-MH battery charger has the same characteristics as PCB design. To design a perfect charger PCB requires a lot of experience. With the development of electronic technology, electronic circuits are becoming more and more complex, and designers need to constantly improve the design level and design more high-quality PCBs.

|

Disclaimer: This article is transferred from other platforms and does not represent the views and positions of this site. If there is any infringement or objection, please contact us to delete it. thank you! |